Regulatory Context Field Implementation, Sample Collection, and Preparation

Before proceeding with field implementation, the following checklist should be consulted to ensure that adequate planning unique to ISM has occurred. Have you:

- DQOs

- identified the problem/decision to be made

- identified objectives/goals

- ensured that the inputs I have designed meet these objectives

- made sure that I understand the CSM (see Section 3.1.2 through 3.1.4)

- DUs/SUs (see Section 3.1.5.1 and Section 3.1.5.2)

- evaluated size and depth relative to decisions to be made

- evaluated if the DU design can be adjusted to serve all data needs (statistics, nature and extent, background, risk assessment, and so on)

- mapped out shape and considered site’s physical constraints

- increments and samples

- identified the appropriate number of increments per DU/SU (see Section 2.5.2 and Section 3.1.5.5)

- identified number of replicates based on site characteristics and heterogeneity (see Section 2.5.3.3 and Section 3.1.5.5)

- considered if pilot or early replicates for unassessed areas are warranted prior to full-scale implementation

- designed an increment sampling path that ensures unbiased locating of increments (see Section 3.1.5.4)

- considered resulting ISM sample size relative to scale of decision-making

- laboratory

- confirmed the processing steps to be conducted by the laboratory (see Section 3.1.5.3 and Section 5)

- confirmed the sample analysis procedures to be used by the laboratory (see Section 3.1.5.3 and Section 5)

- considered QC samples and frequency needed for data validation and statistical analysis (see Section 3.2)

After Section 4, the following checklist should also be able to be completed to ensure proper field preparation and implantation. Have you:

- allocated appropriately trained staff to execute the task

- identified site-specific means of marking out a DU

- calculated the increment size based on the sample design total volume

- identified the appropriate tool(s) to obtain each increment from the required depth

- assessed if a mass reduction technique will be needed during increment collection

- requested/obtained sample containers specific to ISM (large volume, special considerations for VOCs for ISM)

- considered the added resources for sample storage (added ice and coolers)

- communicated to the laboratory the required processing and QC requirements for the chain of custody

4.1 Introduction

The objective of ISM field implementation is to collect increments and produce samples that result in a reproducible estimate of the mean concentrations that control sampling error using practical methods.

The objective of this section is to describe the practical methods for collecting consistently sized increments for surface soil, subsurface soil, and sediment from various environments. The sampling method includes guidance on field planning, locating samples, sampling tools, collection and field processing procedures, decontamination, sample handling, and sample shipping.

This section assumes the systemic planning, DU layout, and statistical sample design have already been completed. Moreover, the DU/SU sizing, location, and thickness have been planned; the number of replicates and increments and the increment layout (systemic or random) have been decided; the laboratory processing steps have been selected; and, from this, a target sample mass has been calculated according to Section 3.1.5. This section will describe appropriate increment sizing to achieve the desired sample mass, the selection of appropriate tools to acquire the increments, procedures for collection and sampling handling, and planning matters to be considered prior to mobilization to allow for efficient and successful field implementation.

4.2 Field Planning

While implementation of ISM sampling has a lot of similar planning steps to conventional discrete soil sampling, there are special considerations to be made prior to field mobilization specifically for ISM. The following sections discuss these considerations, including field personnel training, site conditions and features that impact tool selection, increment sizing to allow for appropriate tooling or bottleware, and special considerations for subsurface investigation.

4.2.1 Field personnel training and staffing

General soil sampling and handling techniques are assumed to be part of the knowledge base for ISM field collection personnel. However, as with all sampling approaches, a basic understanding of the sampling objective specific to ISM can assist in field decisions and allow for collection of improved data. Note that site-specific tooling may vary from those demonstrated in the training; all users should follow manufacturer recommendations to safely and correctly deploy tooling on project sites. A list of commonly used tooling is organized by application in Section 4.3.

With respect to staffing, although ISM sample collection may be performed by a single individual, a two-person team is often the most efficient method. Ideally, one person collects the increments, and the other holds the sample container (such as a clean polyethylene bag) and keeps track of the number of increments. However, site conditions may dictate that three or more individuals are required for the collection of a single ISM sample.

4.2.2 Site conditions, surface features, and soil characteristics

| Soil density across the DU should be similar. Contaminant distribution within different soil types should also be considered when determining DUs. |

Whenever possible, data collection within each DU should be completed during stable weather conditions. Sampling across a DU may require more time than other grab sample techniques – for example, variability in extreme heat/cold, wind, rain, or snow may necessitate a delay in sampling activities to ensure moisture consistency between replicates or SUs. Variable moisture can result in longer sample dry times and other sample handling problems. As such, planners should account for the weather forecast prior to mobilization.

Soil density across the DU should be reasonably uniform (meaning the same general soil classification can be expected throughout the DU). Surface features such as asphalt, vegetation, gravel, and so on should be considered as well. When the surface of the DU contains both vegetated and non-vegetated areas, it is likely that less soil (less increment mass) will be obtained from the vegetated regions within the DU. If a site has obvious areas with different soil lithologies and/or densities (such as areas of sand with areas of fat clay, areas of peat, and so on), those different soil type areas should be factored into DU determinations (location, shape, size of DUs). Assumed differences in contaminant concentrations in the different soil types should also be considered. In these cases, it may be necessary to redefine the DU to account for the possible heterogeneity of contaminant concentration. Moderately different soil types within a single DU may warrant different sampling tools (such as for areas of a DU with increased gravel), which requires the sampler to ensure that increment sizing remains consistent between the different tools.

Extensive discussion of DU design is provided in Section 3, however, in some cases, these DUs may have been designed or established in a desktop environment based on historical information. Current site features encountered in the field may warrant reevaluation of DUs, and the project team should be notified. Field personnel should be conscious of the potential impact of DU heterogeneity on data collection and results.

4.2.3 Increment sizing

Based on the required final mass of the ISM sample as dictated by the sampling design (refer to Section 3.1), the minimum mass and/or volume of individual increments must be calculated prior to sampling to allow for the selection of appropriate collection tools.

The mass of any single increment depends on the depth of interest, soil density, moisture content, and the diameter or size of the sample collection tool. Individual increment mass should be similar, provided the soil density and DU thickness are fairly uniform. Typically, however, individual increments are not weighed in the field during collection. Similar mass per increment is assumed with similar volume collected. Due to practical limitations, increments of similar volume rather than of similar mass are collected, provided that the thickness of the DU is fairly uniform.

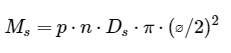

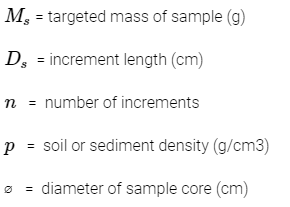

The number of increments to be collected per DU, the sampling depth, and the targeted mass of each sample should all be specified in the sampling design. The following formula can be used for estimating sampling equipment requirements (such as the core diameter) based on a predetermined sample mass and number of increments by adjusting the variables as needed (Walsh 2009):

where

Figure 4-1 is an example for estimating how much mass will be collected for the total sample for a given soil density and number of increments.

Source: ITRC ISM-1 Team, 2012.

4.2.4 Special planning for subsurface assessment

As discussed in Sections 2 and 3, DUs are, by definition, three-dimensional in nature and intended to focus the investigation on a specified volume or mass of soil. Obtaining good spatial coverage and data quality for subsurface soils can be more challenging but is nonetheless achievable. The objectives for subsurface investigations may be similar in nature to surface investigations – for example, the goal may be to estimate the representative concentration of targeted contaminants for targeted depth intervals (within the defined vertical limits), to determine or confirm the lateral boundaries of the source area, or for remedial purposes, to estimate contaminant mass within the DU (say, the mass of tetrachloroethene for the design of a soil vapor extraction system or the mass of dioxins to design an in situ thermal desorption system).

The practical application of ISM sampling to subsurface assessment must be carefully considered during project planning and factor in the labor- and equipment-intensive operations associated with obtaining subsurface sample volume. Sampling of a surface DU in the same spatial area may only require a hand tool corer and sample containers. However, sampling the same area in the subsurface may require the sampler to use drilling equipment, perform numerous borings (often 30 to 90 shallow borings), or use mass reduction techniques, all of which significantly contribute to the resources required for sampling. Often, alternative sampling techniques (such as discrete sampling, field screening, or field analytical methods) may be more practical, applicable, and/or cost-efficient (see Section 3.4) compared to subsurface ISM sampling, but under limiting conditions related to budget, time, or site access, subsurface ISM can be adapted to meet project objectives.

4.2.5 Sample containers

| The analytical laboratory should be consulted prior to sample collection to discuss sample containers, sample handling, solvent type and volume, shipping of samples in methanol, anticipated analytical detection limits, etc. |

Sample containers should be selected based on the predetermined sample volume. Sample containers capable of holding a minimum of 1 kg of soil are recommended. Additional container considerations include analytes, soil type, moisture, and plan for field collection – for example, do you plan to collect increments directly into the sample container or into a larger bucket first for later transfer to the sample container? In most non-volatile analyses, a 1-gallon resealable plastic bag is appropriate, however, plastic is not compatible with certain analytes and regulatory programs, so multiple 1-liter glass containers or high density polyethylene (HDPE) may be needed.

| ISM samples can be collected for VOC contaminant analyses, with ISM increments placed directly into the appropriate volume of methanol in the field. |

To avoid the loss of volatiles associated with the heavy processing that occurs with typical ISM samples, VOC ISM samples require special bottleware consideration:

- Bottles that have a narrow neck or other means of restricting volatilization losses and containing the volume of appropriate solvent[1] should be prepared prior to the sampling activity. Typically, the bottle and solvent are prepared and pre-weighed at the laboratory prior to shipment to the field. This method allows for laboratory calculation of the final ISM soil mass. The volume of solvent should at least equal the mass of soil that will be introduced (1:1), thus, the sample mass must be predetermined. The headspace to preserved sample ratio (methanol + sample) should be less than or equal to that commonly achieved with discrete methanol VOC preserved samples (that is, ~32 mL headspace to 8 mL preserved sample). Soil increments should remain completely submerged in methanol at all times. If increments are combined in the field, it is important to use a volume of methanol large enough to accommodate all the increments.

- The larger volume of methanol could be subsampled in the field prior to shipment to the laboratory. With this option, the complete ISM methanol-preserved sample is disaggregated and extracted in the field by shaking periodically for at least 24 hours, allowing the solids to settle, decanting or pipetting 20 to 30 mL of methanol into a vial, and shipping this aliquot to the laboratory for analysis. The total mass of the ISM soil sample, as well as the total volume of methanol, must be recorded and provided for the laboratory.

- Increments for VOC analysis could be collected and preserved with methanol individually (for example, 5 g soil in 5 mL methanol in volatile organic analysis vials per USEPA SW-846 Method 5035A (USEPA 2002f)and submitted to the laboratory for a combination of methanol aliquots before analysis. The laboratory would remove equal aliquots of methanol from all individual increment vials and combine them in a single vial to represent the complete ISM VOC sample, using the methanol handling techniques described in USEPA SW-846 Method 5035A (see Figure 5-11). This option also allows for analysis of individual increments or alternate combinations of increment groups, if required. Additionally, this option allows flexibility for varying the number of increments without having a large variety of large volume ISM sample bottles. Disadvantages include increased supplies, labor costs, and sample tracking logistics.

- Similarly, but with some field combination, volatile subsets could be collected in groups, preserved with methanol in the field in larger volumes of methanol, and submitted to the laboratory for combining before analysis. For example, six increments of 5 g each would be collected in an appropriate container containing 30 mL of methanol, then five of these volatile subsets would be collected for a 30-increment ISM sample and submitted to the laboratory. The laboratory would then combine equal methanol aliquots from the five subsets for analysis.

- Individual increments could be collected in separate sampling devices that have vapor-tight seals and are designed for zero headspace (Core N’ One™, EnCore, or equivalent type samplers), and then submitted to the laboratory at the appropriate temperature and within appropriate time frames (typically 24 to 48 hours) for combined placement in methanol before analysis.

- Unpreserved soil volume for percent moisture should be collected in the same manner as the ISM VOC samples, with a second increment collected at each ISM increment location and placed in an unpreserved container (4 oz or larger) and submitted to the laboratory.

A potential drawback of ISM for VOCs is that the methanol preservation approach does result in lower sensitivity. The methanol dilution step causes elevated analytical detection limits compared to the direct soil purge-and-trap and low-concentration method techniques. Analytical detection limits could be elevated above relevant screening levels for certain targeted contaminants. Selective ion monitoring (SIM) methods can also be considered to improve the detection limits. The industry is continually researching and updating approaches for this methodology, and current guidance can be referenced for newer and/or better approaches.

4.3 Field Locating

Field locating refers to the process of defining a DU, increment sampling points, and planned travel paths. The importance of field locating is a process used with other sample collection methodologies and further discussed in the following sections.

4.3.1 Locating increments

For a square, rectangular, circular, or other naturally or structurally defined DU (such as a 5-m perimeter around the exterior of a building) on an open plane, DU boundaries can be located with a field tape and subdivided or gridded into uniform cells or subareas based on the desired number of increments to be obtained. However, for oddly shaped, obstructed, vegetated, or uneven terrain DUs (mountainous, hummocky, steep), a global positioning system (GPS) or global navigation satellite system (GNSS) device could be used to delineate the DU and help space the increments. This approach requires layout of the grid over the DU in computer-aided design (CAD) or geographic information system (GIS) and loading of the grid/increments into the GPS or GNSS prior to mobilization.

Depending on the size of the DU and terrain features, placement of markers (such as pin flags and posts) at the corners or edges can assist with a visual delineation of the cells or subareas where increments are to be collected. These markers can define, for example, lanes, grids, and collection points.

When DUs are square or rectangular, the conversions for the spacing (steps) between increment collection points (cells) are fairly straightforward to calculate – for example, a square-shaped DU can be divided into five rows, with six increments collected from each row. Row lengths and increments per row can be modified as needed for oddly shaped DUs, as well. However, with other shapes, it is recommended that the perimeter be marked and flags prepositioned across the DU in one or more perpendicular lines. Then a trial run with no sample collection can be performed to quickly establish the distance between increment collection points to achieve the desired number of increments, using the flags as guides. In these instances, the grid layout may result in plus or minus the target number of increments.

It is not typically necessary to document the exact location of each increment after collection as is typical with discrete samples. The increments contributing to the DU mean are not assessed individually and will not require precise recollection or reproducibility.

4.3.2 Sample approaches and travel paths

Sample increments can be collected using one of three different approaches: simple random sampling, random sampling within a grid, and systematic random sampling. Examples of these travel paths are depicted in Section 3.1 and summarized in Table 4-1. The travel path approach will have been selected during the planning stages to meet the DQOs, but field planning for the selected travel paths prior to collection of the increments in each DU is recommended, especially for the larger DUs based on the number of replicate samples. For example, a DU with a lot of terrain and vegetation may require more preparation of the travel path than a mown level lawn where a grid is easily laid out in the field.

As discussed in Section 3.3, the goal of increment spacing is to represent each part of the DU equally and without bias. Even spacing of replicates serves two purposes: the classical stats assumption of independent field replicates (Section 3.2.6.7) and spatial consideration of hot spot size that is able to be incorporated (Section 2.5.2.3).

Table 4-1. Unbiased increment collection design (see Figure 3-5 for a visual comparison).

Source: ITRC ISM Update Team, 2020.

| Simple Random Sampling | Random Sampling in Grid | Systemic Random Sampling |

| The selection of all increment’s locations in a DU by random selection without gridding (formal approach to random sampling is required). | The DU is divided into a grid and random (computer-based) selection of the location in each cell of the grid is performed. | The DU is divided into a grid, a random sampling location is identified within the first grid cell, and the remaining increments are obtained from adjacent grid cells at the same relative location.

Replicates repeat this pattern in another location within each grid cell. |

4.4 Sampling Tools and Methods

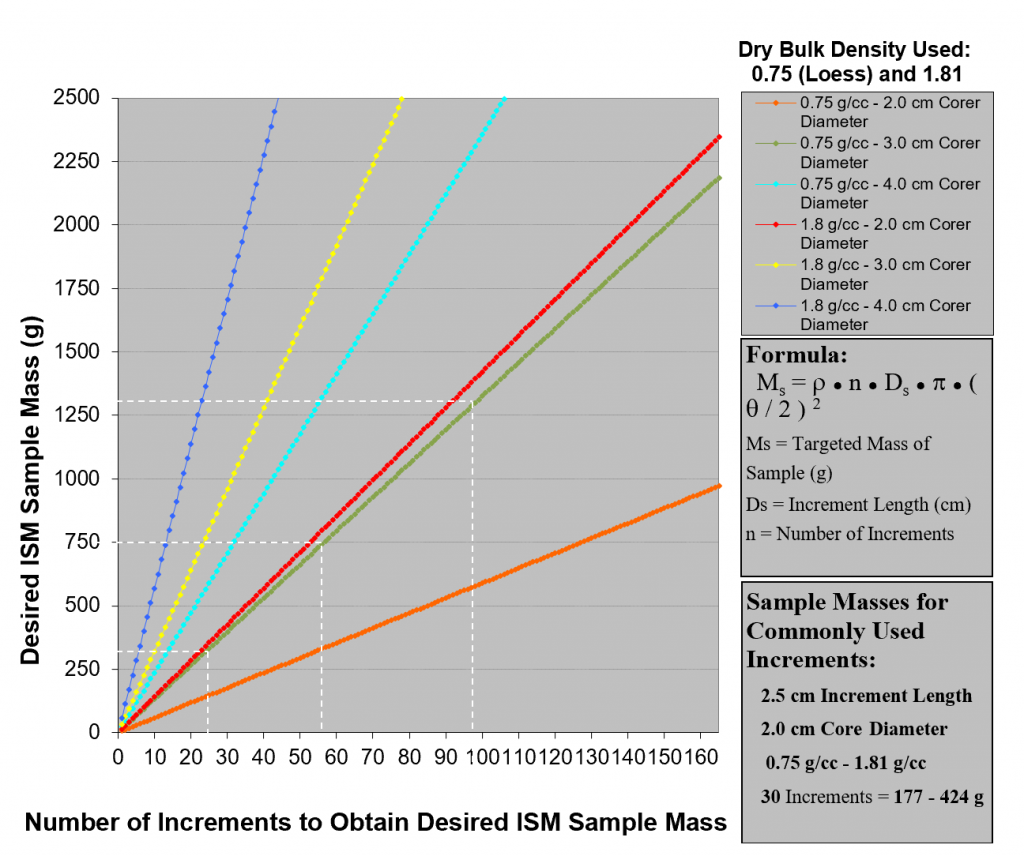

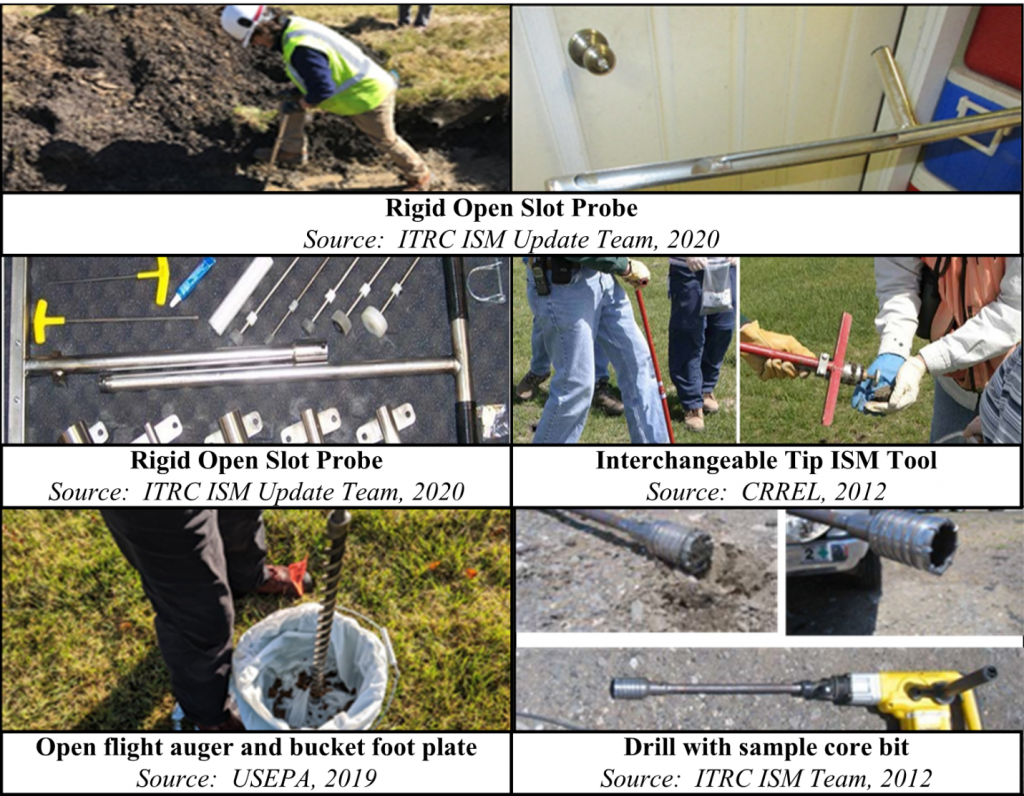

The selection of the appropriate sampling tool for an ISM sample depends on the cohesiveness and composition of the soil substrate. To minimize the increment extraction and delimitation errors described in Section 2.5.5, the sampling tools should meet the following criteria:

| The sampling tool should obtain cylindrical or core-shaped increments of a constant depth from the presented surface, when possible. |

The sampling tool should obtain cylindrical or core-shaped increments of a constant depth from the presented surface.

- The sampling tool should be capable of collecting an appropriate increment size considering the target sample volume required to be submitted to the laboratory and the number of increments (see Section 4.1.4).

- The diameter of the sampling tool should be a minimum of three times the diameter d of the largest particle present in a coarse matrix (d ≥ 3 mm), so 3d + 10 mm for a fine material (Pitard 2019). In general, sampling tools should have a diameter of at least 16 mm.

- The tools shall equally retain all particles over the entire depth of interest. For less cohesive soils, attempts should be made to retain the entire, complete core increment.

- The sampling tool should consider the nature of the contaminant being analyzed. Sample tools for non-volatile compounds or metals would be different from those used for VOCs.

- The sampling tool should consider operator safety and success. Power tools may be required for dense, hard, dry soil or clays.

- A variety of tools to address different soil types or site conditions should be taken into the field for any given project.

See Table 4-2 for examples of sampling tools for both volatile and non-volatile ISM sample collection and Figure 4-2 for examples of sampling tools for ISM collection of VOCs. These are provided as examples only to depict the general equipment – specific brands are not endorsed, and many different brands of equipment are available on the market. Various other hand augers, core sampling tools, step probes, and so on are available from environmental or agricultural suppliers and are applicable to ISM if the specifications meet project DQOs.

Table 4-2 ISM sample equipment.

Source: ITRC ISM Update Team, 2020.

| Equipment1 | Analysis | Surface Soil | Sediment | Subsurface Soil | Soil Excavation Sidewall/Base | Stockpile Soil | |||

| VOC | Non-VOC2 | Loose/Fine | Compact/ Course | Shallow | Deep | ||||

| Flat-bottomed scoops, trowels, or sampling spoons (to be used in conjunction with appropriate increment measuring device) | X | X | X | X | X | ||||

| Thin-walled sampling tube or coring device | X | X | X | X | X | X | |||

| Rigid probe (open-slot push probe, alligator probe, tile samplers); be aware of tip cross-contamination issues | X | X | X | X | |||||

| Interchangeable tip tool (limited in depth; more options for courser soil) | X | X | X | X | X | ||||

| Electric hammer and spade bit | X | X | X | ||||||

| Narrow spade, pri bar, and/or mattock | X | X | |||||||

| Drill with open flight auger, foot plate, and bucket collector (requires overdrilling to obtain bottom of increment) | X | X | |||||||

| Drill with sample core bit | X | X | X | X | |||||

| Hand auger | X | X | X | X | X | ||||

| Drive sampler (manual, hydraulic, or electric) | X | X | X | X | |||||

| Plastic syringe/plug tool | X | X | X (?) | X | X | X | X | X | |

| Sediment sampling tube | X | X | |||||||

| Vibracore device with sampling tube | X | X | X | ||||||

| Direct push rig with drill rods | X | X | X | X | |||||

| Solid stem/hollow-stem augers with split-spoon/barrel samplers | X | X | X | X | |||||

| Sonic drill rig with core sleeves/bag | X | X | X | X | X | X | |||

| Backhoe bucket/loader bucket | X | X | X | ||||||

| Rotary Drilling (air and mud) | X | X3 | X3 | ||||||

Notes:

1 This list is in addition to the typical equipment required for all sample acquisition.

2 Sample collection activities for energetics must occur only in the presence of military explosive ordnance disposal (EOD) personnel or qualified unexploded ordnance (UXO) technicians (US ACE, “Protocols for Collection of Surface Soil Samples at Military Training and Testing Ranges for the Characterization of Energetic Munitions Constituents.” July 2007.

3 To be used with caution and for specific application.

Source: ITRC ISM Update Team, 2020.

4.4.1 Surface soil and sediment ISM sampling

Surface soil ISM sampling is the collection of increments from an exposed and readily sampled (save vegetation) layer of soil or sediment at the surface. The grid and sampling pattern should be laid out according to Section 4.2, and in some instances, practicing the sampling path prior to the actual collection of increments can facilitate the process.

The ISM sampler starts in one corner or end of the DU and collects an increment using an appropriate sampling tool. Determination of sampling paths is discussed in Section 4.2.2. Increments are placed in an appropriate container (such as a bucket, bowl, bag, or jar), and this process is repeated at all remaining increment positions with all the increments placed together in one container. The total increments now represent the ISM sample for that DU, replicate, or SU, and should be provided to the laboratory and not further homogenized or subsampled (other than the ISM processing procedures described in Section 5). This process can then be repeated for a second and third (or more) replicate or SU.

If surface DUs are thick (more than 1 ft below ground surface), some elements of the following subsurface ISM sampling (see Section 4.3.2) and mass reduction sections (see Sections 4.5.1 and 4.5.2, respectively) may become applicable.

4.4.2 Subsurface soil ISM sampling

ISM subsurface sampling is typically completed by using techniques that produce a core that meets the size and shape characteristics discussed in Section 4.3 and increment size needs discussed in Section 4.1.3. Examples of subsurface sampling techniques include direct push techniques to extract cores in liners, thin-walled hollow metal tubes, split-spoon samplers, or sonic drilling core bags. The primary difference between sampling accessible surface soil and subsurface soil is the added resources needed to obtain the increments. This often requires numerous (30 to 90) borings for a single DU to obtain the increments.

| Collection of the entire core interval depth as the increment is the recommended subsurface ISM procedure. |

Ideally, to be representative, the entire core depth interval should be considered as an increment, and then collected, combined with additional increments for an ISM sample, and submitted to the laboratory. Collection of the complete core interval as an increment is the recommended subsurface ISM procedure. However, this method can result in large ISM samples (approximately 5 to 10 kg), making logistics, such as field storage and shipping, problematic. Additionally, the selected laboratory must have facilities available to store, dry (if required), and process these large amounts of soil mass. Consequently, depending on the core diameter and interval depth, inclusion of the entire core increment across a targeted depth interval in an ISM sample may be impractical. In such cases, individual cores may be subsampled to reduce the final mass of the ISM sample. There are some subsurface core sampling options:

- collect an entire core interval (most preferred but results in large ISM sample mass)

- collect a core wedge subsample that reduces the mass of the total ISM sample (most practical)

- collect core slice subsample (least preferred)

When sampling the entire core, the equipment is advanced to the targeted DU depth interval, and the entire core is collected into a container. Decontamination of equipment between increment borings is not required unless two depth intervals are targeted from each core. Similarly, in the case of direct push, core liners can be reused between increments if the sampling design and soil type are such that the liners do not need to be cut to retrieve the increment.

Increments are placed in an appropriate large container capable of containing the final ISM sample volume, and this process is repeated at all remaining increment positions and borings with all the increments placed together in one container. The total increments now represent the ISM sample for that DU replicate or SU, and this sample volume should be provided to the laboratory and not further homogenized or subsampled (other than the ISM processing procedures described in Section 5). This process can then be repeated for a second and third (or more) replicate or SU.

Mass reduction techniques to decrease the final sample volume of the above procedure are described in Sections 4.5.1 through 4.5.2.

4.4.3 Sidewall and confirmatory ISM sampling

An incremental sample result is specifically designed to estimate the mean concentration in a volume of soil designated as a DU. The use of ISM samples to confirm excavation of a source area DU can be highly advantageous over the traditional approach of a small number of discrete samples. The excavation floor and sidewalls can be treated as individual DUs (Figure 3-31) with the investigation objective of assessing whether the estimated mean concentration of COPCs for these areas has been effectively reduced to below targeted screening levels or cleanup goals. This approach may require dividing a large sidewall DU into smaller SUs to meet additional DQOs (such as a certain grid spacing). Additionally, an entire excavation can be considered a DU – individual sidewalls can be sampled as SUs to provide spatial information and then collectively used to assess the effectiveness of the entire excavation (the DU) at meeting cleanup goals. Whatever the sidewall/confirmatory sampling design and objective, collecting ISM samples within these areas rather than single discrete samples ensures good DU spatial coverage and a more representative estimate of mean COPC concentrations at the excavation limit.

There may be regulatory limitations to this approach, however. For example, if regulations require cleanup of releases to a not-to-exceed regulatory level (the maximum concentration determined by discrete samples), then an ISM mean concentration may not be applicable and/or accepted by the regulating authority.

Sidewall/confirmatory sampling is implemented similarly to surface soil since the soil is generally exposed, but sidewalls of certain excavations (deeper than 3 to 4 ft) present their own unique challenges for collection due to limitation on safe access to certain increment locations.

For shallow excavations less than 3 to 4 ft below ground surface, the sampler can enter the excavation (after ensuring that this procedure is compliant with any site-specific health and safety rules), and depending on the sample design, the DU/SU can be marked on the sidewall using a downscaled approach similar to that described in Section 4.2. Pin flags can be used to mark the grid or increment locations, and the DU replicates/SU ISM samples can be collected using any of the simple random, systemic random, or random sampling in a grid approaches. For deeper excavations beyond 3 to 4 ft that are not shored or sloped for egress (a basic test pit hot spot excavation), safe access may limit the application of systemic random and random grid sampling approaches, and simple random may be the only option.

Samples are collected similarly to surface soil ISM samples. The ISM sampler starts in one corner or end of the DU/SU and collects an increment at the predetermined increment positions using an appropriate sampling tool. Increments are placed in an appropriate container, and this process is repeated at all the remaining increment positions with all the increments placed together in one container. The total increments now represent the ISM sample for that DU replicate or SU, and this sample volume should be provided to the laboratory and not further homogenized or subsampled (other than the ISM processing procedures described in Section 5). This process can then be repeated for a second and third (or more) replicate or SU.

4.4.4 Stockpile ISM sampling

There are special considerations for selecting DUs during the SPP for sampling soil stockpiles:

- the source of the soil in the stockpile

- how the stockpile was created (over time, if applicable)

- how best to access the pile for sampling (for example, is it large or unstable)

- contaminants targeted for laboratory analyses

One of the best options is to coordinate sampling with the formation of any stockpiles on a site. When the stockpile is being formed, there is generally good access to sampling each portion of the pile over time, ensuring access to the entire stockpile DU is provided for good sample representativeness. If an existing stockpile is relatively small, good options may include moving the pile and collecting the increments while it is being moved (such as from the equipment buckets at appropriate intervals) or flattening or spreading out the stockpile so that it is safely accessible to sample with a hand core or other device. If the stockpile is very large or unstable, available sampling tools or methods that safely provide access should be considered with the goal of coming as close as possible to collecting a minimum of 30 increments throughout the stockpile (both vertical and horizontal locations). A resource for additional information on ISM approaches for soil stockpile sampling is the HDOH “Technical Guidance Manual”(HDOH 2008b). Refer to Section 3.6.4.2 of this document for additional information on ISM sampling design for stockpiles.

Once the approach to a specific stockpile is determined, the sampling process is comparable to surface soil ISM samples because the soil is accessible, the primary difference being that, in the case of sampling while a stockpile is being created, increments may be collected slowly over a

longer period of time (hours to days) while the soil is being consolidated. Therefore, it is important to document the number of increments after each collection to keep an accurate count.

Stockpile samples are often collected for waste characterization purposes, which are required to be collected at a certain rate per volume/tonnage. Therefore, it is important to ensure that the increments are collected at a rate so as to evenly distribute increments throughout the targeted volume/tonnage. RCRA land disposal characterization does not allow for ISM/composite sampling and requires only discrete sample collection.

During the sample collection, collected increments are placed in an appropriate container, and this process is repeated at all the remaining increment positions with all the increments placed together in one container. The total increments now represent the ISM sample for that DU replicate or SU, and this sample volume should be provided to the laboratory and not further homogenized or subsampled (other than the ISM processing procedures described in Section 5).

4.5 Decontamination

Sampling devices can be used within a DU without decontamination but should be decontaminated or disposed of between DUs (and also between replicates). If sampling tools will be used for two or more DUs, they should be cleaned of soil particles, decontaminated with the appropriate solutions or solvents, and dried between DUs. Typically, rinse (decontamination) blanks can be used to evaluate the potential effects of cross-contamination, if needed.

4.6 Sample Handling and Mass Reduction

| It is recommended that all ISM sample processing be performed in a controlled laboratory setting to minimize sampling errors |

ISM sample processing techniques, such as milling and representative subsampling, are designed to ensure the (typically small) mass of sample analyzed by the laboratory is representative of the DU or SU from which it was collected. These techniques reduce data variability as compared with conventional sample handling and processing approaches, but they also introduce some amount of sampling error. It is recommended that all ISM sample processing be performed in a controlled laboratory setting to minimize these sampling errors; discussion of detailed ISM sample processing is reserved for Section 5. However, there are certain projects that may warrant field sampling processing step(s).

When dealing with contaminants that have been deposited as solid particulates (such as energetics, metals at firing ranges, and so on), field subsampling is not recommended. Studies on energetics have shown that representative subsampling prior to grinding is problematic and likely not possible (Hewitt et al. 2009). However, depending on site logistics, type of soil, total number and/or mass of ISM samples, and so on, sample processing can be initiated in the field for some contaminants (SVOCs, pesticides, PCBs, and metals) with appropriate cautions as noted below. Limitations of the field processing of ISM samples include the following:

- Field processing is not recommended for contaminants deposited as solid particulates (energetics, metals at firing ranges, and so on) because subsampling solid particulates without properly grinding the sample mass may lead to samples that are not representative of site conditions.

- There is a lack of commercially available and correct subsampling tools (16-mm flat-bottom scoop with sides) for proper field processing procedures.

- Sample processing requires a controlled environment to air-dry, sieve, and subsample, if necessary, to minimize the potential loss or introduction of contaminants of concern (COCs) during sample processing.

- Additional subsampling replicates are needed to be collected and analyzed in a laboratory setting to evaluate analytical precision. This requires more knowledgeable and trained personnel.

- Moist samples may need to be air-dried to facilitate sieving in an appropriate dust-free location where temperatures and ultraviolet (UV) light are controlled. This requires an indoor location or job trailer.

Samples with little vegetation and composed mostly of sands and silts that naturally have a very low moisture content and soils that have been air-dried can be sieved in the field to remove pebbles and vegetative debris. Prior to air-drying, sieving, or both, the field-moist sample weight should be recorded. Additionally, field sieving is an option that allows the user to calculate the mass of a bulk ISM sample that will go to a laboratory to ensure that the adequate volume is submitted. It also allows the sampler to control the particle size of the sample to meet DQO requirements. Unless field subsampling will be performed, the entire sieved ISM sample fraction should be submitted to the laboratory for appropriate processing and subsampling.

| If ISM processing and/or subsampling is performed in the field, subsampling replicates are recommended to evaluate precision. |

Finally, if ISM sample processing and subsampling is performed in the field, it is recommended that at a minimum three replicate subsamples be collected and submitted to the laboratory for analysis. The subsampling process (as described above) is repeated on oneISM sample to form replicates, and the replicate results are then used to evaluate the precision of the field processing and subsampling. Note that the subsampling replicates should be collected in addition tothe ISM field replicates described in Section 5.3.5.

Mass reduction is another form of sampling handling that is important to ensure that manageable sample volumes are collected and submitted to a laboratory. Simply dividing an ISM sample (sieved or not) into separate volumes and placing each volume into separate sample containers or selecting a targeted sample volume from a larger ISM sample for analysis is not an acceptable method of mass reduction. Likewise, manually mixing samples to “homogenize” them in the field or laboratory may just serve to further segregate different particle sizes as the particles may settle in layers by weight or size during mixing. It is imperative that an entire ISM sample volume (the total increment) be submitted for ISM processing/laboratory analysis. The ability to submit appropriate sample sizes is controlled through proper sample design and the sample mass reduction techniques further described in the following subsections.

4.6.1 Sample handling and mass reduction for non-volatile analysis

Ideally an entire soil core would be submitted to the laboratory for processing, however due to storage limitations of the laboratories this is not practical. To resolve this issue the following techniques can be implemented during sample collection in the field so representative samples can be provided to the laboratory for analysis.

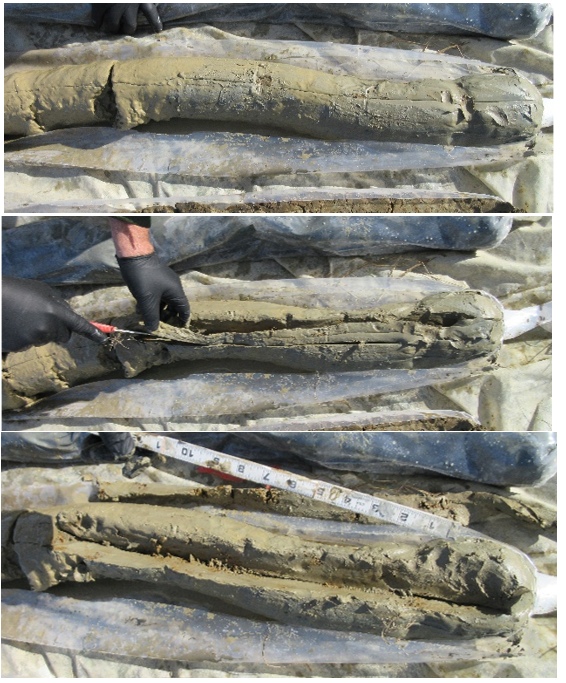

4.6.1.1 Wedge sampling

| Subsurface ISM increment collection techniques in recommended order are as follows: Collect entire core interval Core wedge subsample Core Plug subsample Core slice subsample |

One option for collecting a representative subsample from a subsurface core increment for non-volatile contaminants is to collect a core wedge sample. The simplest approach is to split the core in half vertically along the axis, reducing the increment mass by half. Alternatively, a smaller wedge of soil (say, one-third of the core) can be taken from the entire length of the targeted depth interval. Removing a wedge of soil across the length of a larger core to encompass the entire depth interval rather than collecting the entire core depth interval as a whole reduces the mass of an individual increment of an ISM sample (see Figure 4-3) while still representing the entire depth. Individual wedges from 30 or more separate DU cores are then combined to form the complete subsurface ISM sample. ISM field replicates require completely separate incremental (that is, core) locations and collection of replicates using multiple wedges from the same core cannot be used as a measure of DU or overall sampling and analysis variability. ISM field replicates are discussed in Section 3.1.5.5. Core wedge replicates (i.e., wedge replicates from the same core) may also be collected when COPCs require separate laboratory processing procedures (see Section 3.1.5.3 and Section 5.2).

Source: ITRC ISM Update Team, 2020.

Replicates can be collected from the same core, combined with other wedge increments, and submitted as separate ISM samples to assess the precision of this subsampling strategy. This process reduces the total number of borings required to collect replicates (30 borings compared to 90 for replicates). However, core wedge replicates are not the same as ISM field replicates because ISM field replicates require completely separate incremental (that is, core) locations. Thus, core wedges should not be used as a measure of DU or overall sampling and analysis variability. Core wedge replicates evaluate only the variability in the subsampling process as opposed to collecting the entire core interval as the increment. ISM field replicates, on the other hand, provide information on spatial variability and the variance in the estimate of the mean without specifically separating out the contribution of field and/or laboratory sample processing/subsampling from other sources of variance. ISM field replicates are discussed in Section 3.1.5.5. Core wedge replicates may also be collected when COPCs require separate laboratory processing procedures (see Section 3.1.5.3 and Section 5.2).

4.6.1.2 Plug subsampling

Source: ITRC ISM-1 Team, 2012.

One option that is less preferred than wedge sampling but more practical in certain soil types is a plug sampler (Figure 4-4). Using this method, a designated number of plugs is collected from the desired increment length, from 30 or more separate cores, and then combined to form the complete subsurface ISM sample. This method is considered inferior to wedge sampling because unlike wedge sampling, where the entire length of the core is represented in the increment, only the randomly selected plug locations represent the increment – other portions of the interval are excluded. However, as some soil types prohibit cutting the soil wedge, the plug approach is increasingly practical.

Replicates can be collected from the same core, combined with other plugs, and submitted as separate ISM samples to assess the precision of this subsampling strategy. Similarly to wedge sampling, this process reduces the number of borings (30 borings compared to 90 for separate replicates), but it does not assess the overall DU variability.

4.6.1.3 Core slice

The least preferred option for subsampling individual subsurface cores for non-volatile contaminants is to collect a core slice from the targeted DU layer (Figure 4-5). In this approach, a randomly selected perpendicular slice from within the larger targeted depth interval is collected as the ISM increment. For example, if the targeted depth interval was 2 ft in length (8 to 10 ft bgs), a 4-in perpendicular slice would be randomly selected from within the targeted depth interval of each individual core and collected as the ISM increment. Individual, randomly selected core slices from 30 or more separate cores would then be combined to form the complete subsurface ISM sample. This option introduces more bias than the whole core increment or core wedge approaches, but by reducing the increment mass, it addresses some of the logistical issues associated with handling the full core or the wedge increments. That said, this is the least recommended approach for subsurface ISM core sampling because it is the least likely to accurately represent the complete vertical length of the targeted DU layer.

Replicates can again be collected from the same core by selecting another slice of the same thickness, thereby reducing the total overall number of borings needed to collect replicates. It is important to prepare a sorting scheme for these increments so as not to bias one replicate as shallower/deeper than another. Similar to core wedge replicates, core slice replicates are not the same as ISM field replicates because ISM field replicates require completely separate incremental (that is, core) locations. Thus, core slice replicates should not be used as a measure of DU or overall sampling and analysis variability.

Source: Illinois EPA LUST FAQ and BIOTREE websites.

4.6.2 Sample handling and mass reduction for volatile analysis

The core wedge and slice approaches are not appropriate when VOCs are of concern since they can be quickly lost from an exposed surface (Hewitt, Jenkins, and Grant 1995 ). For VOCs, multiple plugs representative of the desired core depth are collected and immediately preserved in methanol (see Section 4.3.5).

When sampling for VOCs, the core may be subsampled by collecting numerous, small (say, 5-g) plugs at regularly spaced intervals along the targeted DU depth interval of the subsurface core. As with VOC sampling of any exposed soil, the plugs are immediately placed in a sampling bottle containing a predetermined volume of methanol. Nominal 5-g plugs of soil can be collected across the core using a VOC coring device (see Figure 5-10). The spacing interval of the VOC plugs along the core interval should be determined during the SPP but may require adjustment in the field based on core recovery in the case of subsurface ISM sampling. The syringe (or other coring device) used to collect the increments should be filled completely so that each increment has the same volume of soil. Additionally, the ISM sampler should be aware of potential volatile loss once the core is opened. As with any VOC soil sample, ISM VOC increments should be collected and preserved as quickly as possible to minimize potential loss. Potential loss of COPCs due to volatilization during collection of ISM increments is expected to be similar to discrete sample collection by USEPA SW-846 Method 5035A for the same sample density across a subsurface core (USEPA 2007).

Note that an unpublished study from Hawaii using a large bottle with methanol-preserved VOCs was stored in the sun and repeatedly opened over the course of the day to simulate increment additions, and VOC recovery was better than 80% for all analytes except dichlorodifluoromethane.

4.6.3 Sample storage

The primary concern for sample storage is acknowledging larger sample volumes, which will require more storage space and additional coolers.

Processed, labeled samples ready for packaging and shipment to the laboratory are typically stored in a cooler on ice, which for the larger ISM volumes means greater quantities of wet ice and more coolers. For bulk samples stored prior to mass reduction, larger ice receptacles may be constructed by using storage bins for regularly shaped containers (buckets) or form-boards and plastic sheeting for long or irregularly shaped bulk samples.

4.6.4 Sample shipping

The primary consideration for shipping ISM samples is the weight of large volumes (larger than traditional discrete samples) and the required storage and shipment temperatures. The increased weight should be considered when estimating shipping costs (see Section 3.4).

When sampling for volatiles by ISM, the shipment of large volumes of solvent to and from the sampling activity can be problematic. When possible, methanol should be transported to the field via a surface transport to avoid or mitigate the volume limitations common in air transport. Guidelines for the transportation of a solvent such as methanol can be found in 49 CFR §172, “Hazardous Materials Table, Special Provisions, Hazardous Materials Communications, Emergency Response Information, Training Requirements, and Security Plans” (DOT 2011). Shipments via air transport may also be required to adhere to International Air Transport Association Dangerous Goods Regulations (IATA 2011).

4.6.5 Sample chain of custody

Typical laboratory chains of custody are not set up to indicate ISM processing and the specific steps requested for a specific project. It is thus important to communicate project-specific requirements to the laboratory and devise a means for requesting ISM processing (and the appropriate steps) in the chain of custody to ensure that the requirements are clearly communicated to the laboratory. Additionally, there are instances where multiple laboratories may be performing different analyses from the same ISM sample, but the ISM sample should not be split between two or more laboratories for separate ISM processing. Because the ISM sample can only be processed by one of multiple laboratories, one laboratory must be selected to perform the processing, and the means of transferring aliquots for analytical analysis to any other laboratory must be coordinated. It is important to ensure that this additional step in the chain of custody is documented. Sample holding times should also be considered in the logistics during field planning. Certain hold times can run short in considering the date of collection, the time to deliver samples to the lab, processing time (especially for wet samples that require extended dry time), transfer to a second laboratory, and laboratory extraction.

[1] Methanol preservation is discussed herein as the most common VOC preservative for soil, but there are other volatile preservatives that can be similarly utilized to preserve specific compounds. The methodology and considerations presented would remain the same.

Click Here to download the entire document.